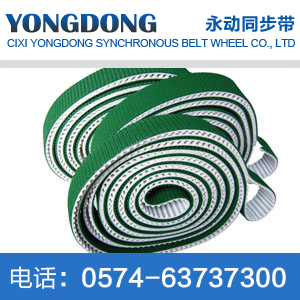

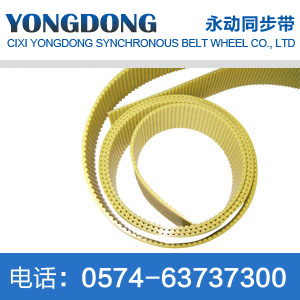

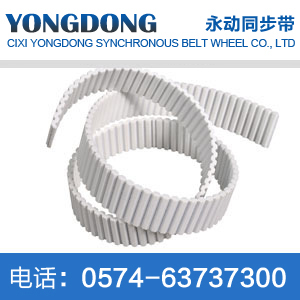

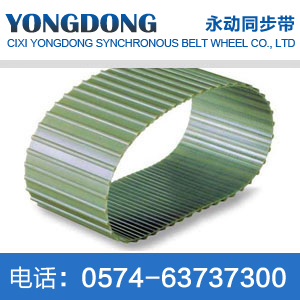

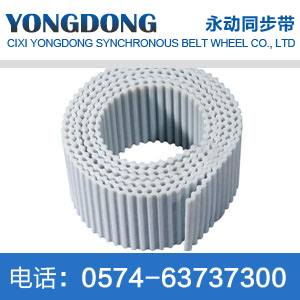

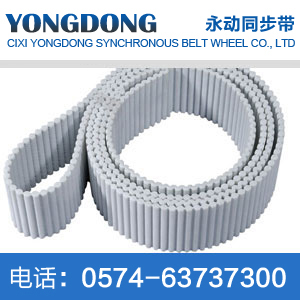

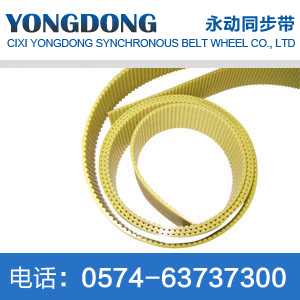

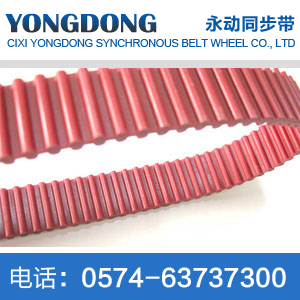

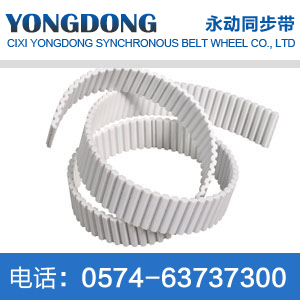

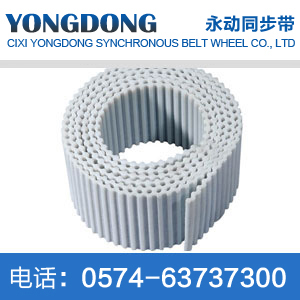

The application of D-L polyurethane double-sided tooth synchronous belt is made of extremely wear-resistant polyurethane, which is 3 to 4 times stronger than black rubber, and the intermediate thermal sealing steel wire or Kevlar wire is formed. Made of thermoplastic polyurethane material, with high wear resistance, various types of steel wire core to ensure that it still maintains good movement ability in the transmission, small production tolerances, can ensure the accuracy of thickness and length Mechanical properties: dimensional stability, low pretension, low noise; High wear resistance, no maintenance, good elasticity; Linear speed up to 80 m/s Chemical properties: anti-aging, waterproof, anti-ultraviolet UVA, anti-ozone.

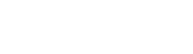

D-L polyurethane double-sided synchronous belt, with light structure, no slip meshing transmission, low noise and other characteristics by the majority of machinery, textile, precision instruments, petrochemical, communication cable and other industries recognized, recognized and widely used. It not only integrates the advantages of gear transmission, chain transmission and belt transmission, overcomes the shortcomings of other transmission belts, such as slippage and elongation, and forms a unique transmission mode, but also has many advantages such as constant speed ratio, large speed range, compact structure, farm multi-axis transmission, oil resistance, moisture resistance, and no lubrication. The successful development of D-L polyurethane double-sided synchronous belt, in the demand for a strip drive and the opposite direction, or the installation position requirements are particularly compact, or in the main drive and auxiliary drive linkage other transmission requirements of the field, all reflect its excellence; Super bending performance, super high tensile strength, accurate meshing, low signal-to-noise ratio and so on.

D-L polyurethane double-sided synchronization belt has the following properties:

Mechanical properties: stable size, low pretension, low noise, high wear resistance, no maintenance, good elasticity, linear speed up to 80 m/s

Chemical properties: anti-aging, waterproof solution, anti-ultraviolet UVA, anti-ozone, highly anti-oil, anti-oil ester, anti-corrosion of most acids and alkalis

Operating temperature: -30℃ ~ +80℃ can withstand up to +110℃ for a short time

Model number | Pitch length (mm) | Number of teeth | Model number | Pitch length (mm) | Number of teeth | Model number | Pitch length (mm) | Number of teeth |

203D-L | 515.62 | 54 | 387D-L | 982.98 | 103 | 697D-L | 1770.38 | 186 |

210D-L | 533.40 | 56 | 390D-L | 990.60 | 104 | 701D-L | 1780.54 | 187 |

214D-L | 543.56 | 57 | 394D-L | 1000.76 | 105 | 720D-L | 1828.80 | 192 |

217D-L | 551.18 | 58 | 397D-L | 1008.38 | 106 | 728D-L | 1849.12 | 194 |

225D-L | 571.50 | 60 | 405D-L | 1028.70 | 108 | 731D-L | 1856.74 | 195 |

233D-L | 591.82 | 62 | 408D-L | 1036.32 | 109 | 765D-L | 1943.10 | 204 |

240D-L | 609.60 | 64 | 412D-L | 1046.48 | 110 | 840D-L | 2133.60 | 224 |

244D-L | 619.76 | 65 | 420D-L | 1066.80 | 112 | 855D-L | 2171.70 | 228 |

255D-L | 647.70 | 68 | 427D-L | 1084.58 | 114 | 863D-L | 2192.02 | 230 |

258D-L | 655.32 | 69 | 435D-L | 1104.90 | 116 | 870D-L | 2209.80 | 232 |

263D-L | 668.02 | 70 | 439D-L | 1115.06 | 117 | 881D-L | 2237.74 | 235 |

265D-L | 673.10 | 71 | 442D-L | 1122.68 | 118 | 900D-L | 2286.00 | 240 |

270D-L | 685.80 | 72 | 450D-L | 1143.00 | 120 | 915D-L | 2324.10 | 244 |

275D-L | 698.50 | 73 | 453D-L | 1150.62 | 121 | 980D-L | 2489.20 | 261 |

277D-L | 703.58 | 74 | 461D-L | 1170.94 | 123 | 934D-L | 2372.36 | 249 |

281D-L | 713.74 | 75 | 465D-L | 1181.10 | 124 | 1028D-L | 2611.12 | 274 |

285D-L | 723.90 | 76 | 480D-L | 1219.20 | 128 | 1148D-L | 2915.92 | 306 |

300D-L | 762.00 | 80 | 495D-L | 1257.30 | 132 | 1192D-L | 3027.68 | 318 |

304D-L | 772.16 | 81 | 510D-L | 1295.40 | 136 | 1406D-L | 3571.24 | 375 |

315D-L | 800.10 | 84 | 518D-L | 1315.72 | 138 | 1418D-L | 3601.72 | 378 |

319D-L | 810.26 | 85 | 525D-L | 1333.50 | 140 | 1675D-L | 4254.50 | 447 |

322D-L | 817.88 | 86 | 540D-L | 1371.60 | 144 | 1998D-L | 5074.92 | 530 |

328D-L | 833.12 | 87 | 548D-L | 1391.92 | 146 | |||

330D-L | 838.20 | 88 | 555D-L | 1409.70 | 148 | |||

334D-L | 848.36 | 89 | 570D-L | 1447.80 | 152 | |||

337D-L | 855.98 | 90 | 574D-L | 1457.96 | 153 | |||

341D-L | 866.14 | 91 | 581D-L | 1475.74 | 155 | |||

345D-L | 876.30 | 92 | 585D-L | 1485.90 | 156 | |||

352D-L | 894.08 | 94 | 600D-L | 1524.00 | 160 | |||

360D-L | 914.40 | 96 | 619D-L | 1572.26 | 165 | |||

367D-L | 932.18 | 98 | 630D-L | 1600.20 | 168 | |||

371D-L | 942.34 | 99 | 634D-L | 1610.36 | 169 | |||

375D-L | 952.50 | 100 | 660D-L | 1676.40 | 176 | |||

382D-L | 970.28 | 102 | 694D-L | 1762.76 | 185 |