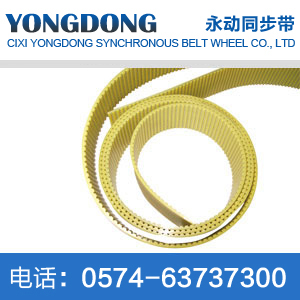

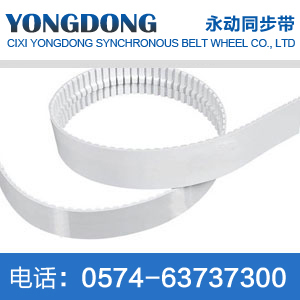

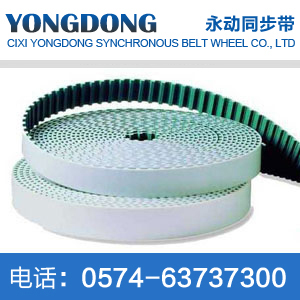

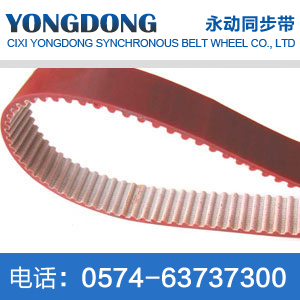

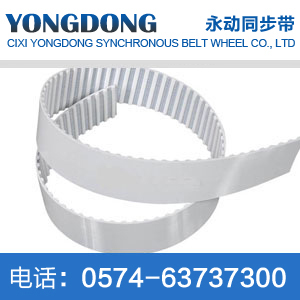

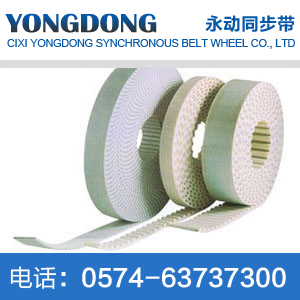

H polyurethane open timing belt is made of thermoplastic polyurethane material, has a high resistance to wear, various types of steel wire core to ensure that it still maintains good movement in the transmission, and small production tolerances. The H-open PU synchronous belt has reliable transmission and dimensional stability. During the production process, a layer of nylon is added to the tooth surface and the back of the domain tooth to ensure that the operation characteristics of the special application are unchanged, and a layer of polyurethane can be added to the back of the belt to prevent corrosion or high load.

H Mechanical properties of polyurethane open synchronous belt

1. Dimensional stability

2, low pretension

3, low noise

4, high wear resistance

5, no maintenance

6. Good elasticity

7, linear speed up to 80 m/s

8, high precision linear positioning

H Chemical properties of polyurethane open synchronous belt

1, anti-aging, waterproof solution, anti-ultraviolet UVA, anti-ozone;

2, working temperature: -30℃ ~ +80℃ can withstand the maximum +110℃ for a short time;

3. Highly oil and grease proof;

4, resistance to most acid, alkali corrosion.

H Polyurethane open synchronous belt ordering needs to know:

H polyurethane open synchronous belt width and length by your own, special specifications can be produced according to your requirements. H polyurethane open synchronous belt is usually used for linear mobile transmission, H polyurethane open with a variety of different core options, such as Kevlar core, steel wire core.

specification | Pitch length | Number of teeth | specification | Pitch length | Number of teeth |

145 H | 368.30 | 29 | 560 H | 1422.40 | 112 |

185 H | 469.90 | 37 | 570 H | 1447.80 | 114 |

200 H | 508.00 | 40 | 580 H | 1473.20 | 116 |

210 H | 533.40 | 42 | 590 H | 1498.60 | 118 |

220 H | 558.80 | 44 | 600 H | 1524.00 | 120 |

225 H | 571.50 | 45 | 630 H | 1600.20 | 126 |

230 H | 584.20 | 46 | 640 H | 1625.60 | 128 |

240 H | 609.60 | 48 | 650 H | 1651.00 | 130 |

245 H | 622.30 | 49 | 660 H | 1676.40 | 132 |

250 H | 635.00 | 50 | 670 H | 1701.80 | 134 |

255 H | 647.70 | 51 | 680 H | 1727.20 | 136 |

260 H | 660.40 | 52 | 700 H | 1778.00 | 140 |

270 H | 685.80 | 54 | 710 H | 1803.40 | 142 |

280 H | 711.20 | 56 | 720 H | 1828.80 | 144 |

285 H | 723.90 | 57 | 725 H | 1841.50 | 145 |

290 H | 736.60 | 58 | 730 H | 1854.20 | 146 |

300 H | 762.00 | 60 | 740 H | 1879.60 | 148 |

310 H | 787.40 | 62 | 750 H | 1905.00 | 150 |

315 H | 800.10 | 63 | 760 H | 1930.40 | 152 |

320 H | 812.80 | 64 | 770 H | 1955.80 | 154 |

330 H | 838.20 | 66 | 780 H | 1981.20 | 156 |

340 H | 863.60 | 68 | 800 H | 2032.00 | 160 |

345 H | 876.30 | 69 | 810 H | 2032.00 | 162 |

350 H | 889.00 | 70 | 830 H | 2108.20 | 166 |

360 H | 914.40 | 72 | 840 H | 2133.60 | 168 |

365 H | 927.10 | 73 | 850 H | 2159.00 | 170 |

370 H | 939.80 | 74 | 870 H | 2209.80 | 174 |

375 H | 952.50 | 75 | 880 H | 2235.20 | 176 |

380 H | 965.50 | 76 | 900 H | 2286.00 | 180 |

385 H | 977.90 | 77 | 940 H | 2387.60 | 188 |

390 H | 990.60 | 78 | 950 H | 2413.00 | 190 |

395 H | 1003.30 | 79 | 960 H | 2438.40 | 192 |

400 H | 1016.00 | 80 | 980 H | 2489.20 | 196 |

405 H | 1028.70 | 81 | 1000 H | 2540.00 | 200 |

410 H | 1041.40 | 82 | 1020 H | 2590.80 | 204 |

420 H | 1066.80 | 84 | 1050 H | 2667.00 | 210 |

425 H | 1079.50 | 85 | 1070 H | 2717.80 | 214 |

430 H | 1092.20 | 86 | 1100 H | 2794.00 | 220 |

435 H | 1104.90 | 87 | 1120 H | 2844.80 | 224 |

440 H | 1117.60 | 88 | 1130 H | 2870.20 | 226 |

445 H | 1130.30 | 89 | 1140 H | 2895.60 | 228 |

450 H | 1143.00 | 90 | 1150 H | 2921.00 | 230 |

460 H | 1168.40 | 92 | 1160 H | 2946.40 | 232 |

465 H | 1181.10 | 93 | 1180 H | 2997.20 | 236 |

470 H | 1193.80 | 94 | 1200 H | 3048.00 | 240 |

480 H | 1219.20 | 96 | 1250 H | 3175.00 | 250 |

485 H | 1231.90 | 97 | 1325 H | 3365.50 | 265 |

490 H | 1244.60 | 98 | 1350 H | 3429.00 | 270 |

500 H | 1270.00 | 100 | 1400 H | 2556.00 | 280 |

510 H | 1295.40 | 102 | 1450 H | 3683.00 | 290 |

515 H | 1308.10 | 103 | 1560 H | 3962.40 | 312 |

520 H | 1320.80 | 104 | 1600 H | 4064.00 | 320 |

525 H | 1333.50 | 105 | 1630 H | 4140.20 | 326 |

530 H | 1346.20 | 106 | 1700 H | 4318.00 | 340 |

540 H | 1371.60 | 108 | 2200 H | 5588.00 | 440 |

550 H | 1397.00 | 110 |