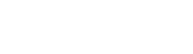

The working principle of the multi-wedge belt wheel is a transmission process which is composed of a plurality of inclined planes and forms a number of hydrodynamic pressure wedges along its circumference when working. Multi-wedge belt, also known as multi-groove belt, is mainly used in engine, motor and other power equipment transmission.

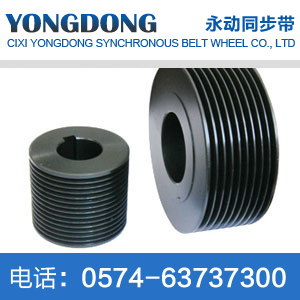

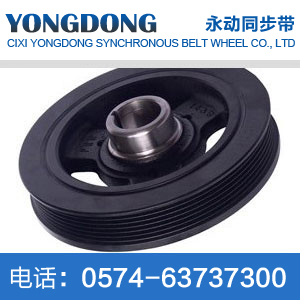

PJ multi-wedge pulley matching PJ multi-wedge belt, Cixi Longyun PJ multi-wedge pulley material to 45# steel, hard aluminum alloy is the most common, other can also choose cast iron, copper, nylon and other suitable materials for processing, the specific selection of customer needs, PJ multi-wedge pulley surface treatment has natural oxidation, black, galvanized, plated zinc, high frequency hardening and other treatment.

Cixi Longyun multi-wedge belt factory can also provide you with PJ multi-wedge belt and PJ multi-wedge pulley drawings production and processing, we can also provide you with multi-wedge pulley inner hole, specifications, width, keyway and other parameters for you to draw the corresponding PJ multi-wedge pulley drawings for precise and accurate processing and manufacturing. As long as you need, we can produce the PJ multi-wedge pulley you need for you.

Cixi Longyun multi-wedge belt factory for you to process the PJ multi-wedge belt wheel used by the equipment is completely CNC! Product quality is fully guaranteed! Will be able to make you really satisfied!

The purpose of Cixi Longyun multi-wedge belt factory: to return customers with the best quality, to support customers at the lowest price, to cooperate with customers at the fastest speed.

Cixi Longyun relies on quality, credit, price and speed, and has become one of the main suppliers of China's transmission industry.

PJ Multi-wedge pulley specifications PJ multi-wedge pulley parameters

Slot distance e 2.34±0.03

Slot Angle a 40°±0.5°

Wedge tip radius rb, minimum value 0.2

Wedge bottom arc radius rt, maximum 0.4

Test ball or cylinder diameter dB 1.5±0.01

2X, nominal value 0.23

2N, maximum 1.22

f, minimum value 1.8

Minimum effective diameter of pulley de 20

Effective line difference nominal value δe 1.2

<td style="box-sizing: border-box; border-color: rgb(85, 85, 85); padding-top: 0px; padding-bottom: 0px; font-size: 14px; color: rgb(34, 34, 34); line-height: 30px; text-align: center; background-color: rgb(240, 240

| Model number | Diameter mm | Number of slots | Model number | Diameter mm | Number of slots | Model number | Diameter mm | Number of slots |

| PJ | 20 | 4 | PJ | 71 | 4 | PJ | 132 | 4 |

| PJ | 20 | 8 | PJ | 71 | 8 | PJ | 132 | 8 |

| PJ | 20 | 12 | PJ | 71 | 12 | PJ | 132 | 12 |

| PJ | 25 | 4 | PJ | 71 | 16 | PJ | 132 | 16 |

| PJ | 25 | 8 | PJ | 75 | 4 | PJ | 140 | 4 |

| PJ | 25 | 12 | PJ | 75 | 8 | PJ | 140 | 8 |

| PJ | 25 | 16 | PJ | 75 | 12 | PJ | 140 | 12 |

| PJ | 30 | 4 | PJ | 75 | 16 | PJ | 140 | 16 |

| PJ | 30 | 8 | PJ | 80 | 4 | PJ | 160 | 4 |

| PJ | 30 | 12 | PJ | 80 | 8 | PJ | 160 | 8 |

| PJ | 30 | 16 | PJ | 80 | 12 | PJ | 160 | 12 |

| PJ | 35 | 4 | PJ | 80 | 16 | PJ | 160 | 16 |

| PJ | 35 | 8 | PJ | 85 | 4 | PJ | 180 | 4 |

| PJ | 35 | 12 | PJ | 85 | 8 | PJ | 180 | 8 |

| PJ | 35 | 16 | PJ | 85 | 12 | PJ | 180 | 12 |

| PJ | 40 | 4 | PJ | 85 | 16 | PJ | 180 | 16 |

| PJ | 40 | 8 | PJ | 90 | 4 | PJ | 200 | 4 |

| PJ | 40 | 12 | PJ | 90 | 8 | PJ | 200 | 8 |

| PJ | 40 | 16 | PJ | 90 | 12 | PJ | 200 | 12 |

| PJ | 45 | 4 | PJ | 90 | 16 | PJ | 200 | 16 |

| PJ | 45 | 8 | PJ | 95 | 4 | PJ | 224 | 4 |

| PJ | 45 | 12 | PJ | 95 | 8 | PJ | 224 | 8 |

| PJ | 45 | 16 | PJ | 95 | 12 | PJ | 224 | 12 |

| PJ | 50 | 4 | PJ | 95 | 16 | PJ | 224 | 16 |

| PJ | 50 | 8 | PJ | 100 | 4 | PJ | 250 | 4 |

| PJ | 50 | 12 | PJ | 100 | 8 | PJ | 250 | 8 |

| PJ | 50 | 16 | PJ | 100 | 12 | PJ | 250 | 12 |

| PJ | 56 | 4 | PJ | 100 | 16 | PJ | 250 | 16 |