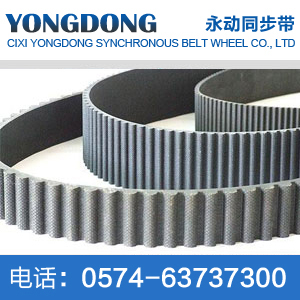

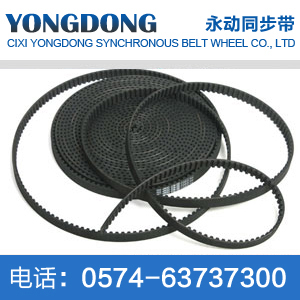

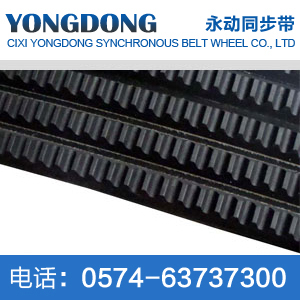

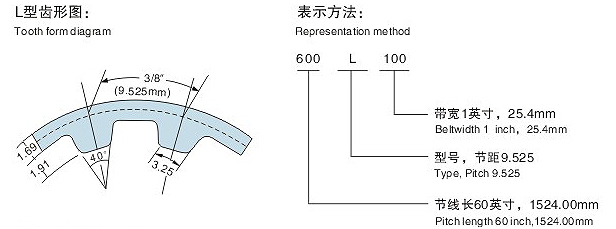

The shape of the teeth is British trapezoid teeth, also known as square teeth, which belongs to the lightweight transmission design.

Standard design reference value: Pitch :9.525mm; Tooth height: 1.91mm; Belt thickness: 3.6mm; Angle: 40 degrees

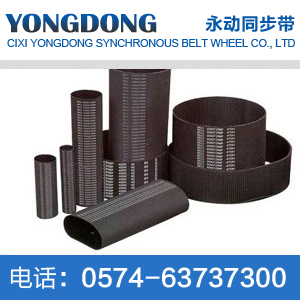

L Rubber single-sided synchronous belt design points:

1, L rubber single-sided synchronous belt for trapezoidal teeth form.

2, L rubber single-sided tooth synchronous belt elastic support and belt teeth combined with durability and light weight.

3, L rubber single-sided tooth synchronous belt with teeth surface nylon 66 high tensile cloth face to protect and strengthen the tooth surface.

4, L rubber single-sided synchronous belt skeleton material using imported high-quality glass fiber rope has very good stability and flexibility.

L Rubber single-sided synchronous belt functional advantages:

1, power transmission up to 150 kW and speeds up to 10,000 rpm.

2, peripheral speed up to 80 m/s.

3, anti-synchronous belt slip.

4, L rubber single-sided tooth synchronous belt constant smooth operation.

5, high efficiency.

5, low bearing load, because L rubber single-sided tooth synchronous belt has a high tension of freedom.

6. Maintenance free continuous operation.

7, a wide range of load capacity and speed ratio.

8. Compact design.

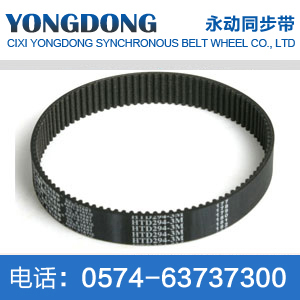

L Rubber single-sided synchronous belt identification:

Three parts: Indicates the length, spacing, and width of the belt brought back by the part number. As shown in the following picture. This L rubber single-toothed synchronous belt model has a 60 inch (1524.00mm) pitch length and a 1 inch (25.4mm) bandwidth.

specification | Pitch length | Number of teeth | specification | Pitch length | Number of teeth |

86 L | 219.08 | 23 | 375 L | 952.50 | 100 |

98 L | 247.65 | 26 | 382 L | 971.55 | 102 |

100 L | 257.18 | 27 | 390 L | 990.60 | 104 |

109 L | 276.23 | 29 | 394 L | 1000.13 | 105 |

113 L | 285.75 | 30 | 397 L | 1009.65 | 106 |

124 L | 314.33 | 33 | 400 L | 1019.18 | 107 |

130 L | 333.38 | 35 | 405 L | 1028.70 | 108 |

135 L | 342.90 | 36 | 408 L | 1038.23 | 109 |

143 L | 361.95 | 38 | 412 L | 1047.75 | 110 |

150 L | 381.00 | 40 | 420 L | 1066.80 | 112 |

154 L | 390.53 | 41 | 427 L | 1085.85 | 114 |

158 L | 400.05 | 42 | 435 L | 1104.90 | 116 |

161 L | 409.58 | 43 | 439 L | 1114.43 | 117 |

165 L | 419.10 | 44 | 442 L | 1123.95 | 118 |

169 L | 428.63 | 45 | 450 L | 1143.00 | 120 |

173 L | 438.15 | 46 | 453 L | 1152.53 | 121 |

177 L | 447.68 | 47 | 465 L | 1181.10 | 124 |

180 L | 457.20 | 48 | 480 L | 1219.20 | 128 |

185 L | 466.73 | 49 | 495 L | 1257.00 | 132 |

187 L | 476.25 | 50 | 500 L | 1266.83 | 133 |

191 L | 485.78 | 51 | 510 L | 1295.40 | 136 |

195 L | 495.30 | 52 | 525 L | 1333.50 | 140 |

203 L | 514.35 | 54 | 540 L | 1371.60 | 144 |

210 L | 533.40 | 56 | 548 L | 1390.65 | 146 |

220 L | 561.98 | 59 | 555 L | 1409.70 | 148 |

225 L | 571.50 | 60 | 560 L | 1419.23 | 149 |

230 L | 581.03 | 61 | 570 L | 1447.80 | 152 |

240 L | 609.60 | 64 | 574 L | 1457.33 | 153 |

244 L | 619.13 | 65 | 581 L | 1476.38 | 155 |

250 L | 638.18 | 67 | 585 L | 1485.90 | 156 |

255 L | 647.70 | 68 | 600 L | 1524.00 | 160 |

263 L | 666.75 | 70 | 619 L | 1571.63 | 165 |

270 L | 685.80 | 72 | 630 L | 1600.20 | 168 |

275 L | 695.33 | 73 | 660 L | 1676.40 | 176 |

277 L | 704.85 | 74 | 675 L | 1717.50 | 180 |

280 L | 714.38 | 75 | 694 L | 1762.13 | 185 |

285 L | 723.90 | 76 | 697 L | 1771.65 | 186 |

300 L | 762.00 | 80 | 701 L | 1781.18 | 187 |

304 L | 771.53 | 81 | 720 L | 1828.80 | 192 |

315 L | 800.10 | 84 | 728 L | 1847.85 | 194 |

319 L | 809.63 | 85 | 731 L | 1857.39 | 195 |

322 L | 819.15 | 86 | 739 L | 1876.43 | 197 |

328 L | 828.68 | 87 | 765 L | 1943.10 | 204 |

330 L | 838.20 | 88 | 791 L | 2009.78 | 211 |

334 L | 847.73 | 89 | 874 L | 2219.33 | 233 |

337 L | 857.25 | 90 | 900 L | 2286.00 | 240 |

341 L | 866.78 | 91 | 982 L | 2495.55 | 262 |

345 L | 876.30 | 92 | 994 L | 2524.13 | 265 |

352 L | 895.35 | 94 | 1043 L | 2647.95 | 278 |

355 L | 904.88 | 95 | 1148 L | 2914.65 | 306 |

360 L | 914.40 | 96 | 1988 L | 5048.25 | 530 |

367 L | 933.45 | 98 |