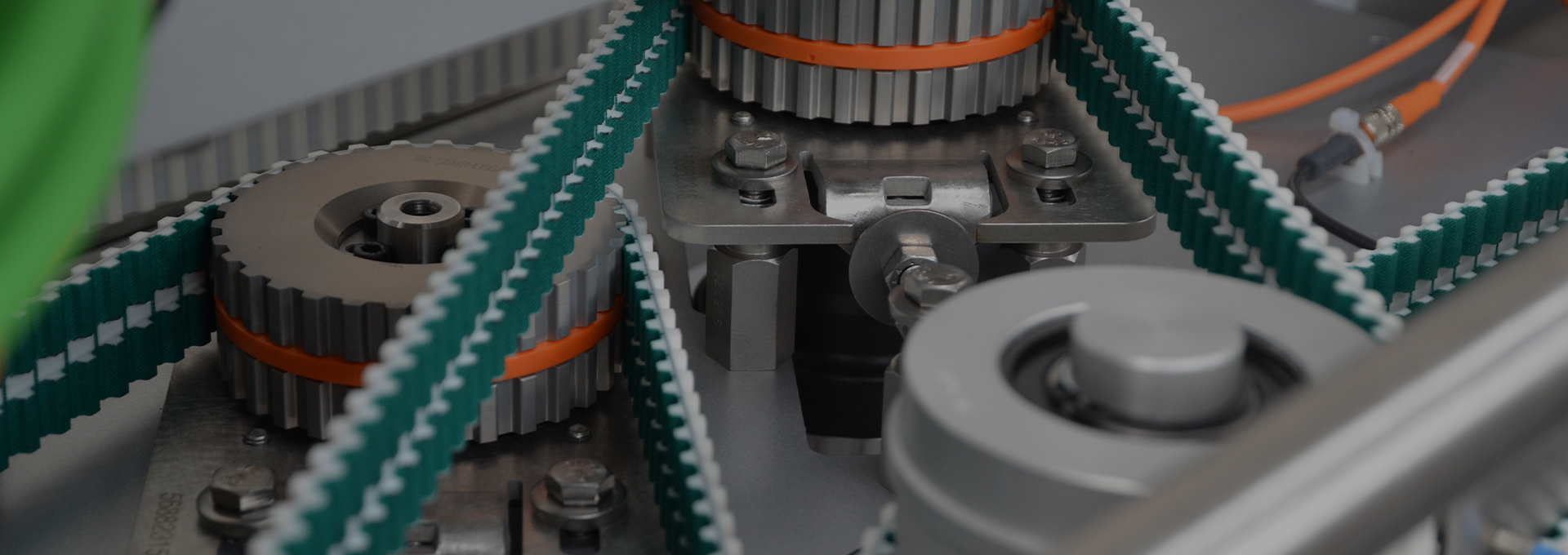

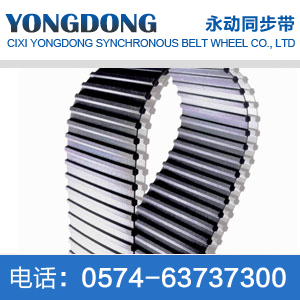

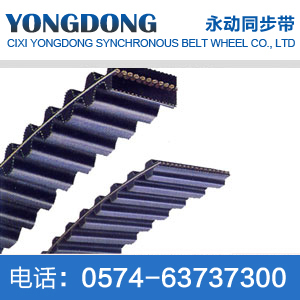

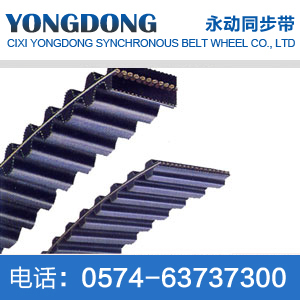

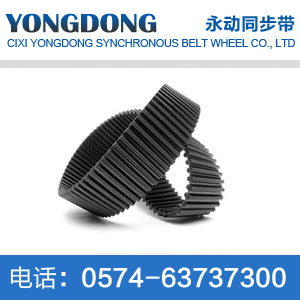

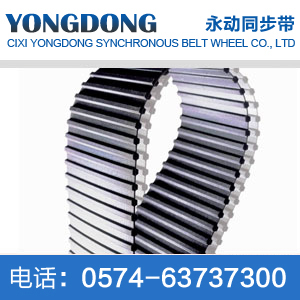

The body layer of D-AT10 rubber double-sided tooth synchronous belt is made of high-quality neoprene material imported from Japan, the skeleton layer is made of high-quality glass fiber rope imported from Japan, and the wear-resistant layer of tooth surface is protected by nylon 66 high-tensile cloth. D-AT10 rubber double-sided synchronous belt has the characteristics of good dynamic bending, good cracking resistance, excellent ozone property, aging resistance, heat resistance, oil resistance, wear resistance and so on.

Precautions for storage, installation and use of D-AT10 rubber double-sided synchronization belt

1, it is strictly prohibited to forcibly break and bend the D-AT10 rubber double-sided tooth synchronous belt to avoid damage to the strong layer and lose the use value.

2. The D-AT10 rubber double-sided synchronization belt shall not be stored in an abnormal bending state for a long time.

3, the D-AT10 rubber double-sided tooth synchronous belt should be kept in a cool place.

4, please shorten the center distance during installation, relax the tension wheel, do not force the belt from the lower flange of the belt wheel hard drag grinding into.

5. The teeth of the D-AT10 rubber double-sided synchronous belt must be at right angles to the running direction of the synchronous belt wheel.

6, the parallelism of the main shaft of the driving wheel and the passive wheel is controlled at tangent =1/1000 or so. The inaccurate axis position directly affects the service life.

7. It is found that the D-AT10 rubber double-sided tooth synchronization belt on the driving wheel is skewed to one side, and the passive wheel should be moved to adjust it and the pressure of the tension wheel should be adjusted.

8, when starting, the center distance changes, D-AT10 rubber double-sided tooth synchronization belt is relaxed, the phenomenon of jumping teeth, should check whether the pulley frame is loose, the positioning of the shaft is out of alignment. Adjust and reinforce.

9, D-AT10 rubber double-sided tooth synchronous belt installation must be according to different models and bandwidth appropriate tension.

10. The tension wheel must be installed on the loose side of the driven transmission.

D-AT10 rubber double-sided synchronous belt drive features

D-AT10 rubber double-sided tooth synchronous belt is mainly used for double-sided transmission, with synchronous, simultaneous, double efficiency characteristics. Its excellence is reflected in areas where a strip drive is required and the direction is opposite, the installation position is particularly compact, or other transmission requirements such as the main drive and auxiliary drive linkage are high; D-AT10 rubber double-sided synchronous belt with light structure, no slip meshing transmission, low noise and other characteristics by the majority of machinery, textile, precision instrumentation, petrochemical, communication cable and other industries recognized, recognized and widely used.

| specification | Pitch length (mm) | Number of teeth |

| D-AT10X500 | 500.00 | 50 |

| D-AT10X560 | 560.00 | 56 |

| D-AT10X580 | 580.00 | 58 |

| D-AT10X660 | 660.00 | 66 |

| D-AT10X730 | 730.00 | 73 |

| D-AT10X840 | 840.00 | 84 |

| D-AT10X920 | 920.00 | 92 |

| D-AT10X960 | 960.00 | 96 |

| D-AT10X1010 | 1010.00 | 101 |

| D-AT10X1150 | 1150.00 | 115 |

| D-AT10X1210 | 1210.00 | 121 |

| D-AT10X1240 | 1240.00 | 124 |

| D-AT10X1250 | 1250.00 | 125 |

| D-AT10X1280 | 1280.00 | 128 |

| D-AT10X1320 | 1320.00 | 132 |

| D-AT10X1500 | 1500.00 | 150 |

| D-AT10X1610 | 1610.00 | 161 |

| D-AT10X1800 | 1800.00 | 180 |

| D-AT10X1940 | 1940.00 | 194 |

| D-AT10X2000 | 2000.00 | 200 |

| D-AT10X2250 | 2250.00 | 225 |

| D-AT10X2590 | 2590.00 | 259 |

| D-AT10X2880 | 2880.00 | 288 |

| D-AT10X3080 | 3080.00 | 308 |

| D-AT10X3150 | 3150.00 | 315 |

| D-AT10X3340 | 3340.00 | 334 |

| D-AT10X4030 | 4030.00 | 403 |